Menü

Przemysłowe systemy przetwarzania obrazu, które pchną Cię do przodu Przesuwamy granice możliwości

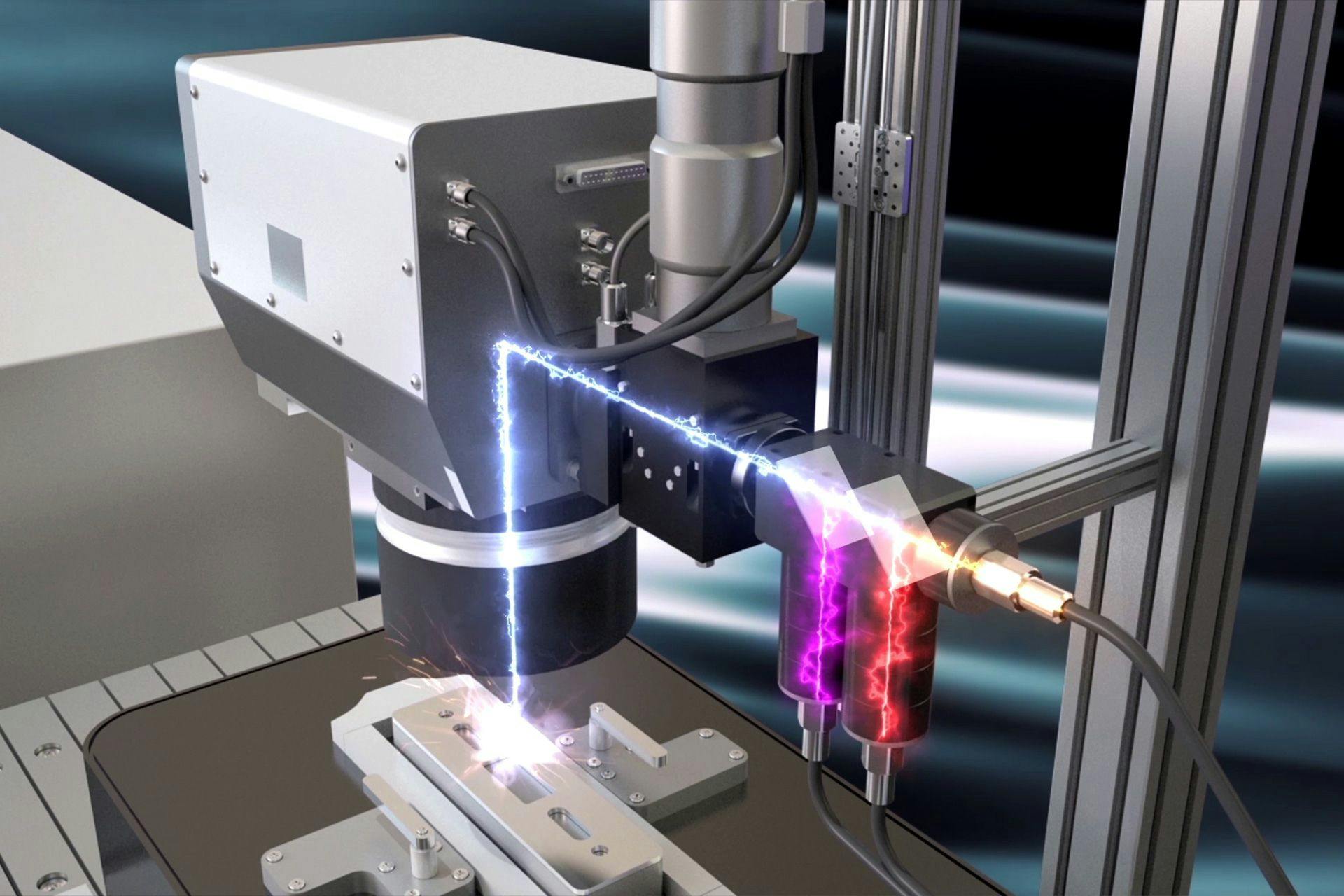

W centrum uwagi: zautomatyzowana kontrola spawów na ramach akumulatorów

W centrum uwagi: Mobilny system egzekwowania

Nasze branże

Nasze systemy przetwarzania obrazu zapewniają bezpieczeństwo, jakość i przepustowość w wielu branżach: